From May 16 to 18, the 15th China International Battery Technology Exhibition was held in Shenzhen. More than 2,500 outstanding battery companies from all over the world participated in the exhibition.

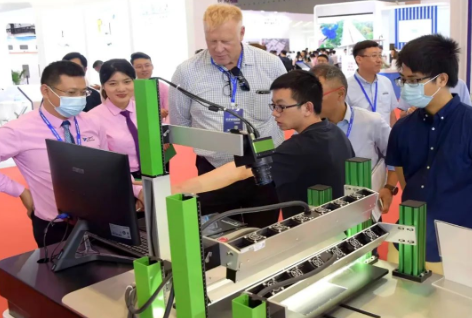

As the core supplier of machine vision in the lithium industry, OPT presented visual detection technologies such as 3D, deep learning and frequency division technology, and displayed hundreds of hardware and software products related to visual detection of lithium batteries, attracting professionals in the lithium industry to stop for consultation and exchange.

Lithium battery 3D visual detection technology, micron level accuracy

In this exhibition, OPT focused on the development trend of lithium battery visual inspection, and showcased 3D visual inspection technology and solutions, including lithium battery top cover welding quality inspection, cell blue film five-sided full inspection, size measurement and other applications.

In order to better cope with the defects of different forms in the polar ear region, OPT makes full use of deep learning detection technology to automatically extract the characteristic information of related tasks to avoid missing detection and misjudgment.

For subtle scratches in different directions, OPT has launched a frequency division detection technology, which is also one of the most frequently asked technology applications by the audience. The trigger signal is controlled by frequency division technology, so that more than two kinds of light sources are stroboscopic in turn, and the image extraction algorithm is used to output the image with obvious defect features, so as to make the detection more comprehensive.